In terms of body armor, the typical steel armor plate that protects the body from projectiles is usually covered with a layer of coating. There is a coating that protects that base metal from the elements, and there is even a type of coating that can protect the metal from ballistic fragmentation.

The difference between spall coating and base coating may be life or death. If the bullets that hit one’s body armor break into pieces, those fragments turn into projectiles that can strike in the face, neck, arms, and legs. Spall coating prevents this. The base coating has a different purpose: protecting the metal plate from the elements.

When a bullet hits body armor, it has to go somewhere. Ideally, body armor absorbs or deflects the bullet. During deflection, that bullet can be shattered. Spall coating is designed to absorb that “spall.” Read on to learn more about how this coating is different from the base coat and what it means for your body armor.

What Are Spalling and Fragmentation?

Spalling and fragmentation are actually two different things, although they are related and dangerous.

- Fragmentation is what happens when the bullet hits the body armor, and pieces fly off.

- Spall is the pieces of body armor that break from the impact of the bullet.

Spall coating and base coat differ in that a typical base coat is just a finishing coat. It makes the steel armor plates look nice and protects them from rust, sweat, or other environmental hazards. While the base coat can offer additional protection just by being another layer over the metal, spall coating or spall liner is made with a different purpose. Spall coating is a soft, thicker layer intended to absorb fragmentation and spalling – to keep frag or spall from injuring the wearer it is trying to protect.

Not All Body Armor is Created Equally

They say not all body armor is made equally, and this is completely true. And when you are dealing with your life and the lives of others, you want to make sure you have the best that you can get. But whether your body armor is made of steel, ceramic, or another material, it is best to have some kind of spall coating to prevent bullets from fragmenting. Getting hit by the fragments of bullets may be better than being hit by a bullet in the chest, but it can still be dangerous or life-threatening. Not just to you but to others nearby you. What if you are trying to protect a child or someone who does not have body armor? You will pull them close and try to protect them.

Where Do Bullet Fragments Go?

If the fragments of the bullets fly from your body armor, chances are the person you are trying to protect could be injured or even killed. That is not an option you want to think about, but you have to consider that the pieces of the bullets will go somewhere. When bulletproof vests first came out, they were made to deflect bullets, but not necessarily with thought given of what would happen to the deflected bullets. Ballistics hit the armor-like glass hitting a wall – they shatter. Bullets turn into dangerously sharp pieces of metal that can do a lot of harm to unprotected soft body parts like your face and neck.

What is FragLock™ and Why is it so Good?

When you consider the spall coating of body armor, you have to think of it as layers of softer metal that can absorb the impact, so the bullets do not shatter as they typically do. One such type of spall coating, FragLock™, has been touted as the best on the market. And if you watch the videos of the coating in action, you will have to agree.

FragLock™ has been engineered and carefully tested to be the perfect thickness:

- Applied thick enough to make the armor safe from fragmenting and spalling.

- Thin enough to be worn comfortably and maneuvered in easily. T

They put their body armor through four stages of preparation and cleaning before being coated. Then the coat is applied by hand to provide the best traction surface.

Steel Ratings Are Important to Note

Another important part of your body armor is the steel that is used for the plate. AR500 is steel that is tempered to be used to reduce abrasions and impacts. The 500 rating is the Brinell Hardness scale that measures the indentation hardness of metal with a scan of penetration. The higher the rating, the better the body armor. Spartan™, Omega™, and Armaply™ come in ratings of AR500, AR550, and AR650, so they are some of the best you can get. Using these high-quality plate carriers and the FragLock™ coating together would make a superior body armor that protects better than anything else on the market.

What Is Encapsaloc™ Coating?

Encapsaloc ™ is a coating system created by Spartan Armor Systems that is a relatively low-cost addition to an already life-saving piece of equipment. Spartan Armor Systems employs a detailed process to ensure this anti-spalling coating is flawlessly applied for maximum function and protection – providing rifle-rated protection. The absorbent composition of Encapsaloc™ traps the fragments from the projectile before they ever become dangerous projectiles.

What Material is Best for Body Armor? Do They All Spall?

People tend to talk about ceramic and steel the most and compare the differences as you would with choosing a favorite soft drink. Everyone has their own tastes and preferences – this may be partially true with body armor. But there is also some science behind it. Body armor is typically made with four types of materials, each with its own pros and cons – some of which have to do with spalling and fragmentation. The most common materials include steel, ceramic, polyethylene, and Kevlar. Well, cover each one of these in detail below.

Steel Body Armor

Steel body armor has been used since WWII and has always been the first thought that comes to mind when you think of bulletproof vests. It was actually first used in 1561 by Filippo Negroli, who developed the first coat of armor for the soldiers in battle. The problem is that the firearms and ammunition we use have been made to be stronger and more powerful. So, armor has had to evolve with the advancements in ammo. The stronger the weapon, the stronger the steel had to be. And to make it stronger, you had to make it thicker. Steel plates in a vest still have the power to stop almost every type of ammunition and shrapnel, but they are heavy. Very heavy. And they can also cause excessive fracturing of the bullets and spalling. This can be dangerous to the wearer as well as those nearby. As we know, steel requires a spall coat to prevent this.

Ceramic Plates

After the steel plates had been around for a while, ceramic plates were developed. This happened around the time of the Gulf War in 1990-1991, although it was used on tanks instead of people. Once they realized how well this material worked and how much lighter it was, they started making ceramic body armor. Rather than having to wear heavy steel plates, soldiers and police officers were able to wear the lighter ceramic plates with the same protection. Almost the same, anyway. Eventually, they found out that ceramic plates cannot take hits to the same spot more than once or twice. Ceramic plates do not spall, which is a big plus. But many ceramic plates need a polyethylene or Kevlar backing to help protect against their relative fragility. It is also this fragility that causes a lack of protection when not handled or installed properly.

Polyethylene Plates

Also known as UHMWPE or thermoplastic armor, this is an ultra-high molecular fiber over a high-density polyethylene sheet. They are then molded together to become one sheet that is even more protective than steel or ceramic. When the bullet hits the plate, it melts the polyethylene layer and sticks to the round. Then when it cools, it is hardened again so it can take more hits. Also, the material is much lighter than both steel and ceramic, making it easier to wear. In terms of spalling and fragmentation, polyethylene is also good for reducing fragmentation as it wraps the bullet in the material. This makes it one of the best choices out there for most types of body armor needs. But it is expensive and cannot stop armor-piercing ammunition.

Kevlar Body Armor

Kevlar seems to be everywhere nowadays, from armor to vehicle parts and even in frying pans and smartphones. This synthetic fiber has high tensile strength. That means it can withstand a lot of stress before breaking. The molecules of the Kevlar are bound tightly together, making them almost impenetrable.

There are three grades of Kevlar.

- Standard Kevlar is stiff and is usually used to make tires and other car parts.

- Kevlar 29 is more of soft body armor and is also used for cables, brake linings, and other important materials.

- Kevlar 49 is usually used for airplanes, boats, and bikes.

But Kevlar is only successful as a soft armor unless it is paired with one of the other materials like steel, ceramic, or polyethylene. That is why Kevlar is usually used to make the vests and other clothing that you insert the armor plates into. It is also damaged by UV rays, so it has to be kept out of the sun and may also be weakened by bleach and other cleaners.

Why Not Just Use Steel for Armored Vests?

Although steel is the most reliable and strongest material, typically used for tanks and other military vehicles, it is heavy and causes fragmentation and spalling. That is why steel covered by spall coating to prevent the chances of that happening is used by most companies. Steel is a great protective barrier, albeit heavy and cumbersome, but it should be coated with spall coating to prevent spalling and fragmentation. Although it is still possible that some amount of spalling and fragmenting may happen, it is highly unlikely. The coating of at least a half-inch of spall-resistant material should protect against that.

Other Important Features of Body Armor

When deciding on body armor, there are many things to take into consideration, in addition to spalling and fragmentation. Here are some of the top factors to consider.

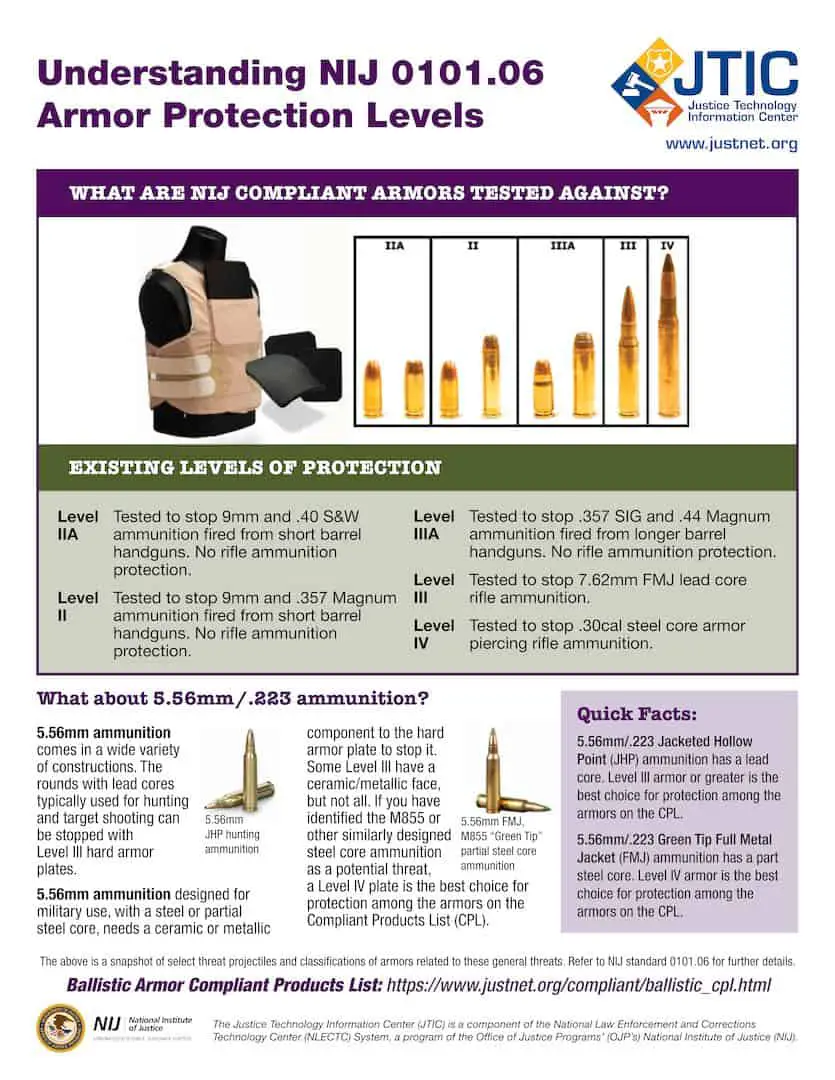

Protection Level

You want to ask yourself what type of protection you may need: Will you be in danger of rifle fire or just have to worry about stab wounds? The ballistic performance for all body armor has strict regimens set by the National Institute of Justice (NIJ), but they also have a stab resistance standard. The NIJ ballistics test checks the body armor for protection from both perforations by bullets and blunt force trauma from the bullets. The stab resistance test specifically checks for the minimum performance of body armor against stabs and slashes from knives and other sharp instruments.

Level of Comfort

It is also important to check for the level of comfort in your body armor. In short, are you able to move around freely with the body armor on, or is the armor too bulky or heavy? Just because something is heavier does not mean it offers better protection. Even though polyethylene and Kevlar are lightweight, they can offer better protection than ceramic plates.

Concealability

Another important feature to consider is whether or not you can hide your body armor well. In many situations, it may not matter whether your armor is concealed or not. But in certain situations, it is best not to advertise that you are wearing a vest. For example, in a tactical operation, if the opposition knows you are wearing body armor, they know where not to shoot.

Care and Maintenance

No matter what type of body armor you get, you will need to maintain it and take care of it. But some need more care than others. For instance, you should never drop or throw your armor, especially if it’s ceramic. And you should check the plates well every time you take them off and put them on. Look for wear and tear as well as curving.

Affordability

Although your life is priceless, you still have to consider costs when purchasing your body armor. There is no reason to spend more than you have to. Some types of body armor can be extremely expensive but still not be as effective as the less expensive ones. You just have to do your homework before buying anything.

Different Levels of Body Armor

There are several different types of body armor. Each type is good for its own purposes, but some are better than others. The most common kinds of body armor used include the following.

- Level 3A Soft Armor: For Handguns and Types 1 through 3-A Threats

With this type of body armor, you have protection from a 44 magnum up to a 9-millimeter submachine gun. This is the best level of protection in body armor that is concealable and used for routine wear with maximum protection.

- Standard Steel Body Armor

This is the heaviest armor, but it is also the least expensive. The plates of armor are able to handle several hits and can even stand up to being hit in the same spot more than once. The steel is good for high concealment since it is thin as well as durable. However, this type of body armor is not as protective against guns with a higher velocity like an M193 or M855. The force of the bullet’s energy can easily pass through the armor and cause broken bones or lethal internal bleeding. Another concern here is the fragmentation or spalling because the frags may hit your neck or face.

- Level 4 Polyethylene Armor: For Armor-Piercing Rifles

With this type of armor, you are getting the most advanced with the highest level of protection. The level 4 polyethylene armor protects from armor-piercing rifles like 30-06 with an impaction of 868 m/s or less. The ceramic plates provide single-shot protection but are heavy and bulky, which can hinder your mobility.

- Lightweight Body Armor: Rating up to Level 3

Made of synthetic fabric and soft armor plates, the lightweight body armor offers excellent protection with better mobility and comfort than the others.

The Addition of Anti-Spalling Coating Is Worth It

Choosing body armor with an anti-spalling coating has become increasingly essential as ammunition gets more advanced. How much can your armor protect you if the bullets that strike it turn into dangerous shrapnel? A base coat may be slightly more effective than bare steel, but it doesn’t do enough. There are some great companies out there making top-notch tactical gear with life-saving anti-spalling. The layer doesn’t add much weight, and whatever cost it adds can never be too much for the protection of your life and that of those around you.

OUR RECOMMENDED TACTICAL GEAR LIST:

- Best Health and Fitness Tracker, Whoop. Get 1 Month Free: See it here!

- EDC Assisted Opening knife we can’t live without: See it here!

- Best EDC Concealed Carry Pistol: See it here!

- Extreme Performance Morning Dink: See it here!

- Best 3D Printer For Gun Parts and Accessories: See it here!

- Our Top Rated EDC Flashlight: See it here!

- AR Red Dot Sight We Can’t Live Without: See it here!

- Best Handgun Safe For Quick Access: See it here!

- Top Wireless Security Camera For Home Security: See it here!

- The Range Bag You’ve Always Been Looking For: See it here!

- CIA Approved Sharp Shooting Course: See it here!